STORY:

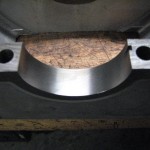

Local luxury car dealership contacted us regarding an engine rebuild for a 2009 Jaguar XF, supercharged model. The engine starved of oil, developed a major rod knock, and spun several main bearings. Complete engine rebuild was in order. Cylinder bores were severely scored and distorted due to lack of lubrication. Custom CP pistons were designed and manufactured specifically for our application and engine bored 0.5mm oversize. Crankshaft rod journal were severely worn and had to be pre-ground, spray welded, and final ground to size. Jaguar does not sell oversize bearings, thus every journal had to be restored to standard OEM size. There was a lot of bearing material in the oil pan and extensive cleaning/flushing necessary before engine reassembly. Engine reassembled using Clevite bearing guard lubricant. Engine break-in performed using Brad Penn 30W “Green Oil”.

PARTS LIST:

- CP 86.5mm forged pistons, pins, rings, and c-clips

- OEM parts:

- oil pump

- oil pick up tube

- rod bearings

- main bearings

- thrust bearings

- main bolts, M10 long

- main bolts, M8 long

- 3 new connecting rods

- valve stem seals

- head gaskets

- valve cover gaskets

- front cover gaskets

- lower oil pan gasket

- Bore/hone block to size

- Hand stone deck to prepare for metal head gasket

- Align hone crankshaft main bearing bores

- Pre-grind, spray weld, final grind crankshaft rod and main journals

- Balance and micropolish crankshaft

- Measure all bearing clearances using micrometers and bore gauges

- File fit piston rings using Childs & Alberts piston ring grinder

- Replace front and rear main seals

- Measure piston deck height

- Measure piston dish volume for compression ratio calculator

- Disassemble, clean, and inspect all components

- Check all valves for runouts using v-block and dial indicator

- Reface all valves using IDL valve machine

- Hand stone deck to prepare for metal head gasket

- Check valve spring pressure using Rimac valve spring tester

- Grind valve shims

- Replace valve stem seals

- Hand lap all valves and check seal

- Reassemble heads

- Measure combustion chamber volume for compression ratio calculator

i have a 2001 xkr jaguar project that i am not sure which way to go yet to get 200 more horses,,,there is a few options on the internet , So my question is whats the cost to stroke my 4liter or get the 4.2 and stroke it ? also what kinds of horse power are we looking at making,,,bare in mind ill get a ported supercharger , ported heads, better radiator for inter cooler . thanx

Hello, how much is the cost to buy CP 86.5mm forged pistons, pins, rings, and c-clips for this engine please and how long for delivery?

Thank you!!

JJB

Hello Jose,

Thank you for the inquiry. We sent you an email.

Hello John,

Thank you for the inquiry. We sent you an email with additional information.

I have 2009 Jaguar XJR. I wrote before not sure if you got it or maybe you are no longer doing this work? I love this car. Unfortunately it leaked coolant and without warning. Engined died wont turn over. Dealer says install new engine but that’s an impossible price to bear more than car is worth. Others I spoke to hesitate to work on this kind of late model car with electronics, I guess I dont know the right people. Compression test shows no compression on 1, 3, 5 & 7. Any advice or thoughts on what can be done to rebuild the engine. Presumably all other engine parts are fine. My first car at age 16 (30 years ago!) was a 1976 XJ6 which I just loved, but it broke down every thursday and spent every weekend at mechanics – hard life for a 16 year old with no car on the weekends 🙂 Others I knew at the time put small block Chevy engines in them. I just traded it in for a new car. Wish I still had it. Got the 2009, last of the classic XJ body style and so I’m sad all over again. I know you cannot quote or diagnose from afar, just curious any advice or thoughts, assuming you only had to rebuild, hone, and replace pistons and rods etc and salvage/reuse all other parts (shaft, superchargers, etc) is it worth doing? I am in CA and I see you are in IL so factor that as well though I am in manufacturing so I have contacts for shipping to/fro. Or maybe you know someone closer to home you would refer to me. Searching for info on the web for this project is not very fruitful your site was the most hope I could find. Thanks -Stephen

Hello Stephen,

Please check your email for a reply with a request for additional information. Typical cost of a basic rebuild is in the $6000 range.

Do you have to reprogram ecm?

Thank you for your interest. This rebuild was done using the stock compression ratio and ECU recalibration was not necessary.