Description

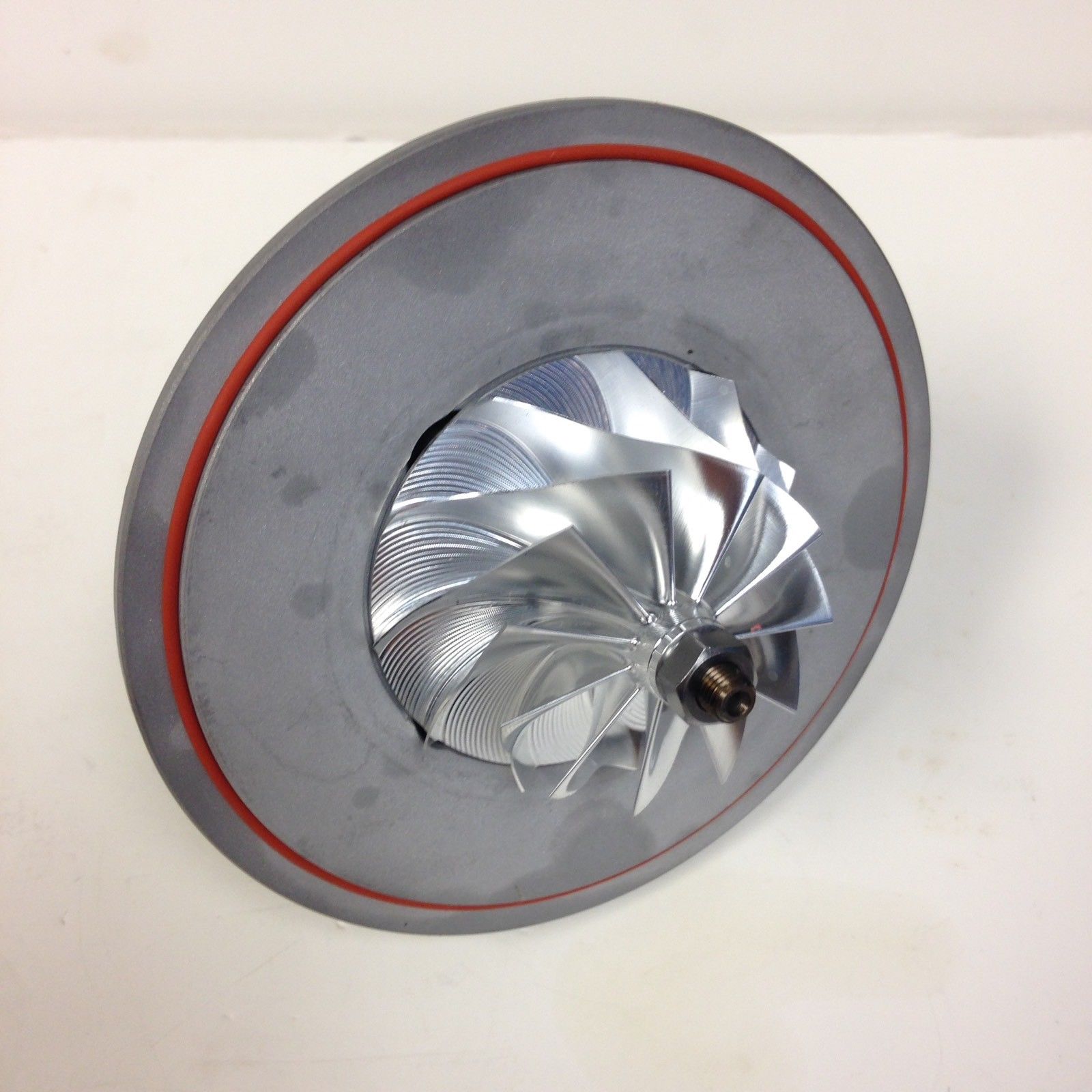

Pavel’s Racing Engines, Inc. is pleased to offer this high-quality billet compressor wheel for IHI VF-series turbochargers. This compressor wheel has been fitted and validated in both street performance reliability applications and tested on the dyno for performance.

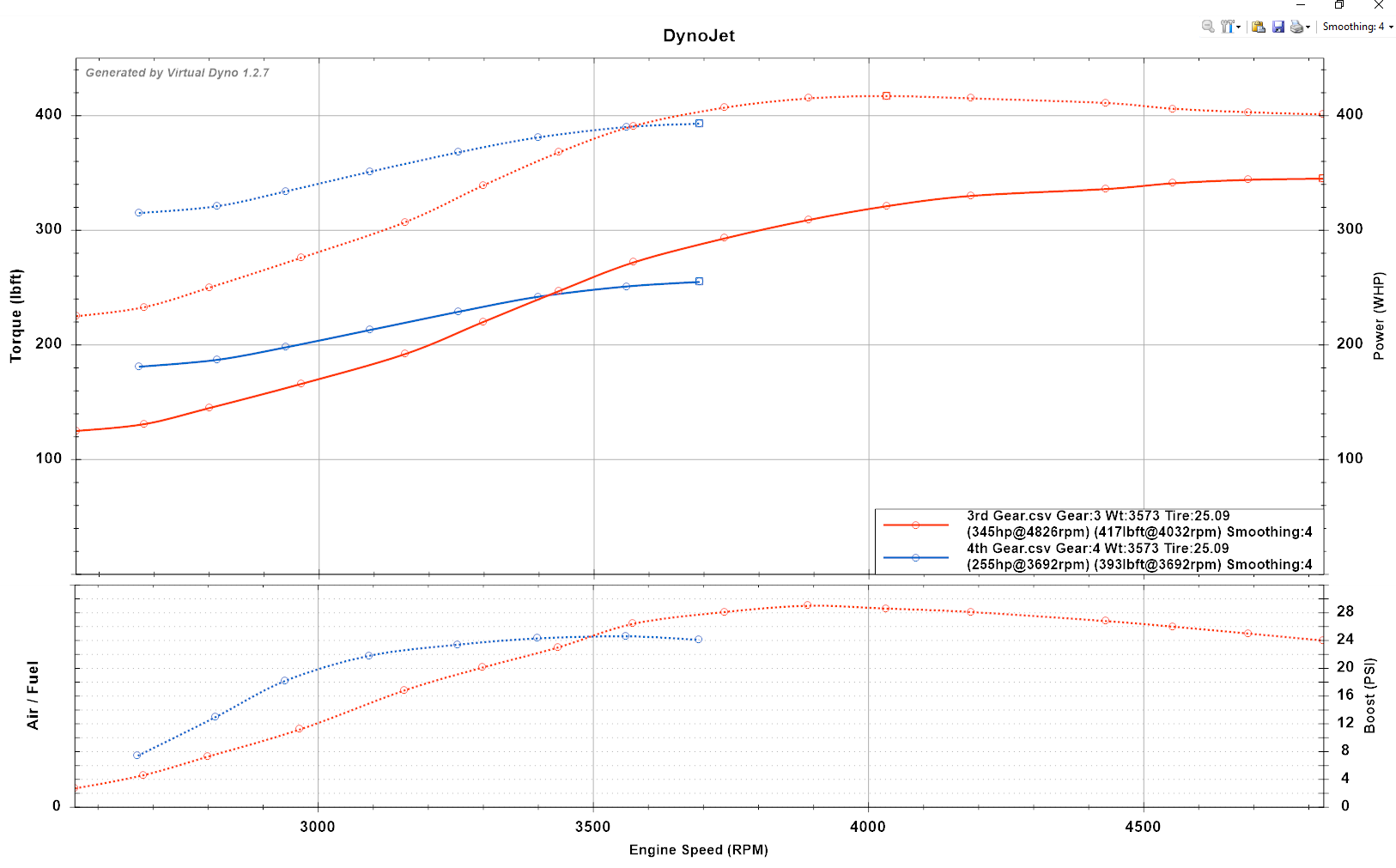

We tested these compressor wheels on a chassis dyno with a consistent 30whp gain at the same boost level as a stock cast compressor wheel. Torque increase was moderate as well in the mid-range RPM. All testing was performed on same vehicles within a narrow time window to reduce erroneous data.

Compatibility:

- VF30

- VF34

- VF35

- VF37

- VF39

- VF41

- VF43

- VF48

- VF52

Standard Features and Advantages:

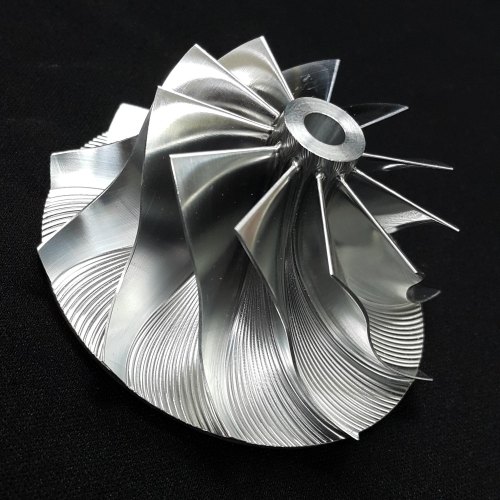

- 11 blade design: Conventional IHI design is 6 tall and 6 short blades. Garrett has proven higher flow potential of the 11 blade design and it has been adopted to this compressor wheel for IHI application.

- Extended tip design: Conventional compressor wheel tips perpendicular to the exducer diameter. Extended tip technology originally developed as “cheater” compressor wheels for racing use. Standard exducer diameter is 60mm, while extended tip compressor wheels had 63mm exducer diameter for total blade area increase of about 6%. This of it like a larger area of an airplane wing allowing for increased lift.The Larger surface area allows for increased flow volume at same turbo speed.

- Slim blade design: Performance feature designed to increase airflow. Slim blades have a smaller cross-section allowing more area between blades for air. Flow is increased at same turbo speed. Thinner blades also weigh less for a reduced moment of inertia and faster spool.

- Slim hub design: Another feature designed to increase airflow. Slim hub increased air volume with each rotation. Flow is increased at same turbo speed. Smaller cross-section hub weighs less for a reduced moment of inertia and faster spool.

- Material selection: Conventional compressor wheels made by casting aluminum alloy. PRE compressor wheels machined from billet aluminum alloy block. Billet blocks are forged. This compacting of molecules increases material density and strength. Increased strength of billet material allows for a reduced blade and hub cross-section and weight reduction without increasing internal stresses.

- Balancing: PRE compressor wheels inspected and computer balanced to less than 0.5g-cm^2. This does not mean compressor wheel should be swapped as-is. Stack-up dis-balance is always a factor and compressor wheel balancing should always be performed by a professional using entire rotating assembly.

We offer complete IHI VF39 rebuild service. We can replace turbine shafts, compressor wheels, oil seals, journal bearings, thrust bearings, housings, and perform balancing service.

Turbo rebuild prices start at $300. Please inquire about cost and lead time for your specific situation.

Thank you for your interest in Pavel’s Racing Engines Inc. products and services.

Reviews

There are no reviews yet.