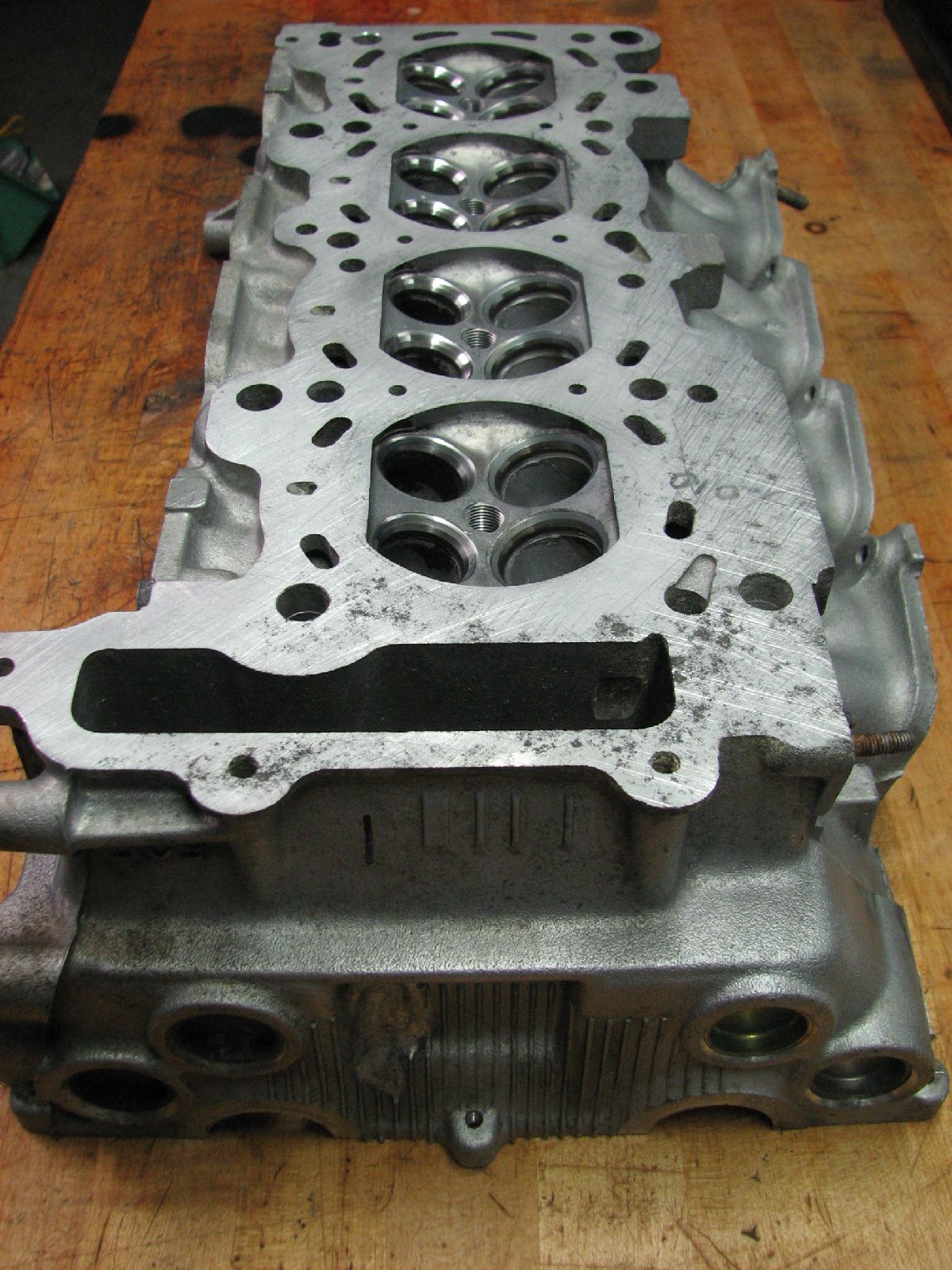

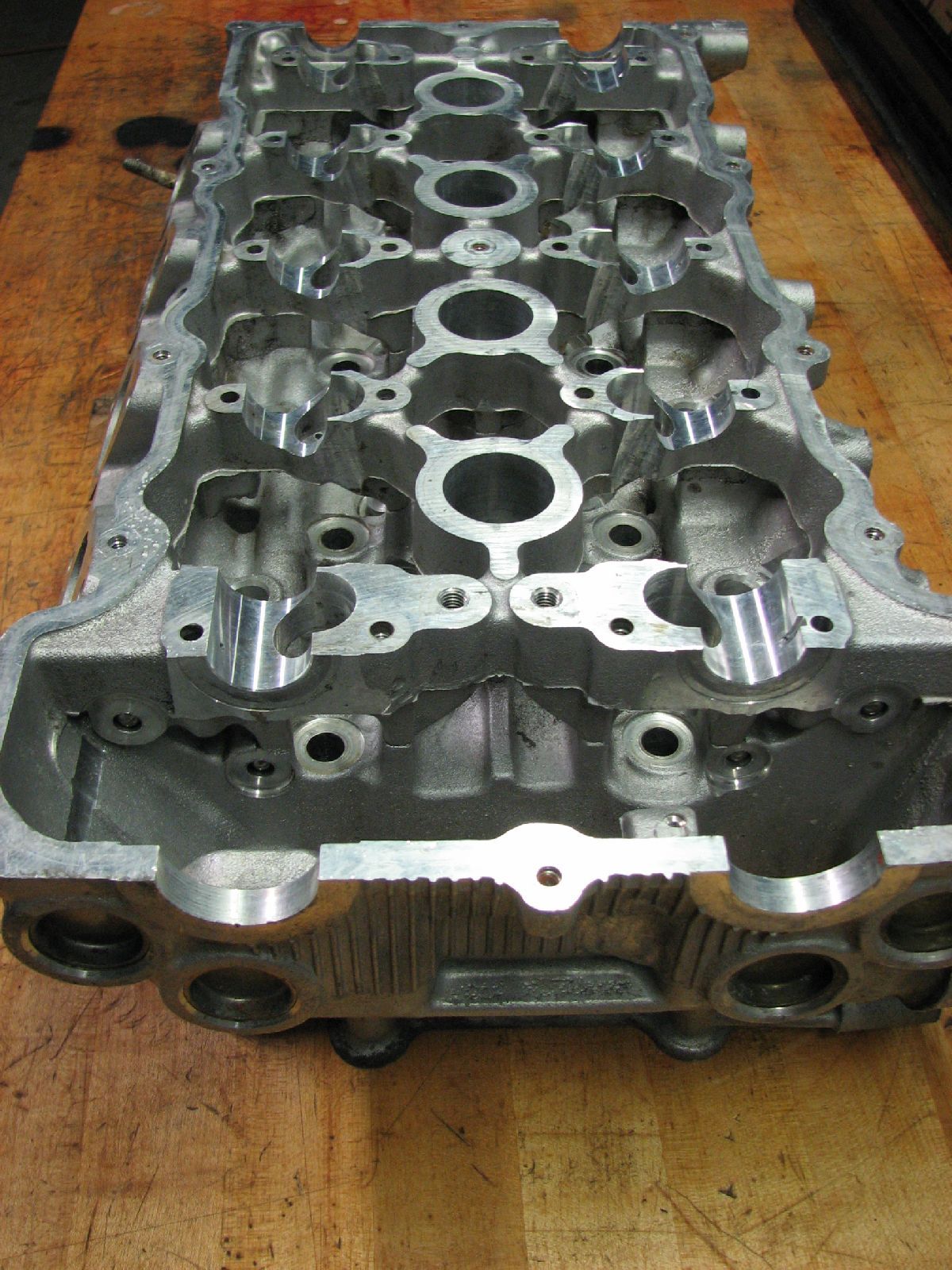

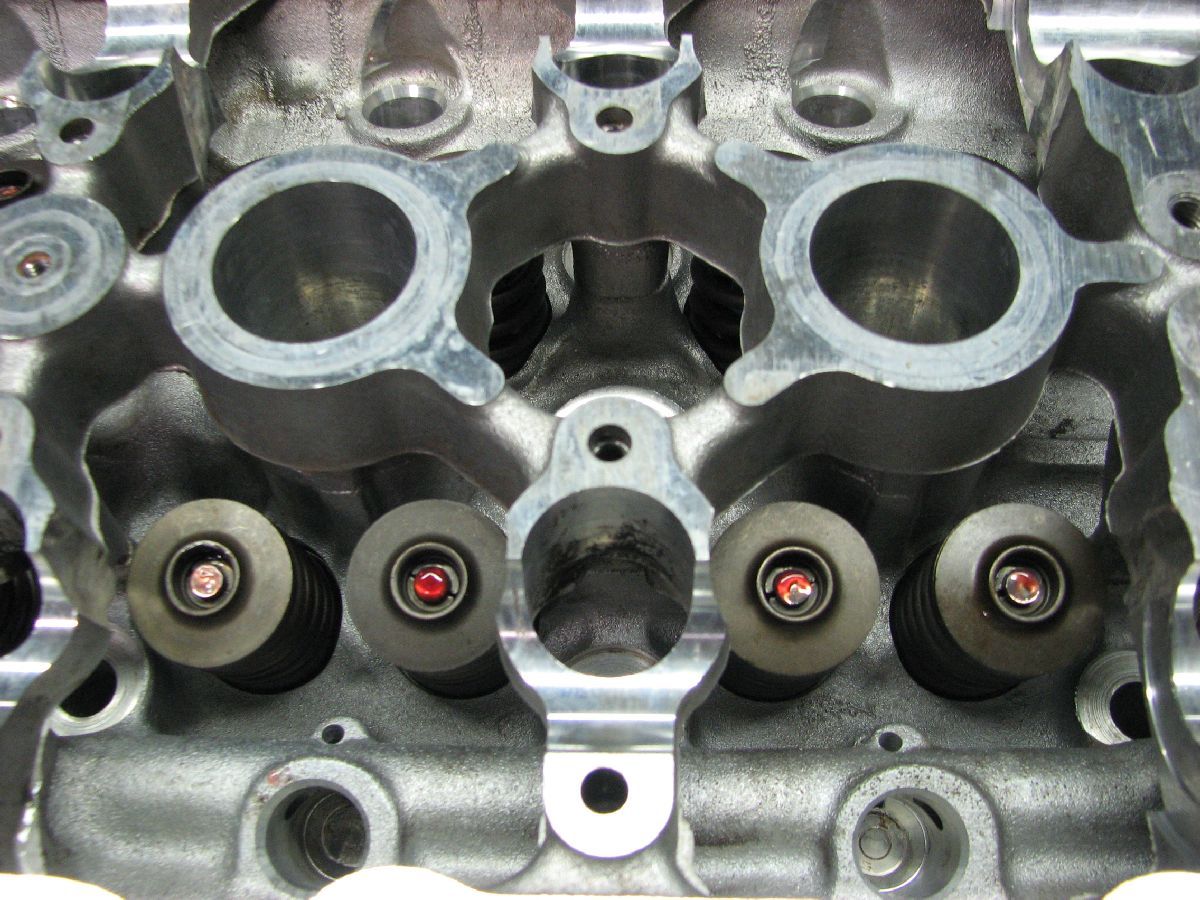

Here is another SR20DET cylinder head we rebuilt at PRE. This cylinder head came to us in very poor condition. Customer wanted a OEM style rebuild. Upon complete disassembly and inspection it became obvious actual condition of the cylinder head. Cylinder head gasket mating surface was slightly warped, exhaust valve guides worn beyond factory limit, valves pitted, and valve seats showed unacceptable wear. Since this cylinder head is going on a performance engine intended for high speed auto cross and drifting we had to make sure every specification was better than factory. This is what separates engine builders, attention to detail.

Work performed:

Cylinder head gasket mating surface checked using precision straight edge

Valve seats checked for out-of-round using precision seat concentricity gauge

All valves checked for bends and out-of-round using v-block and dial indicator

Exhaust guide clearances checked using Sunnen P310 valve guide gauge

Exhaust guides replaced with manganese bronze units

Exhaust guides honed to spec using Sunnen P190 valve guide hone

All valves refaced using IDL/Sunnen valve grinding/refacing machine

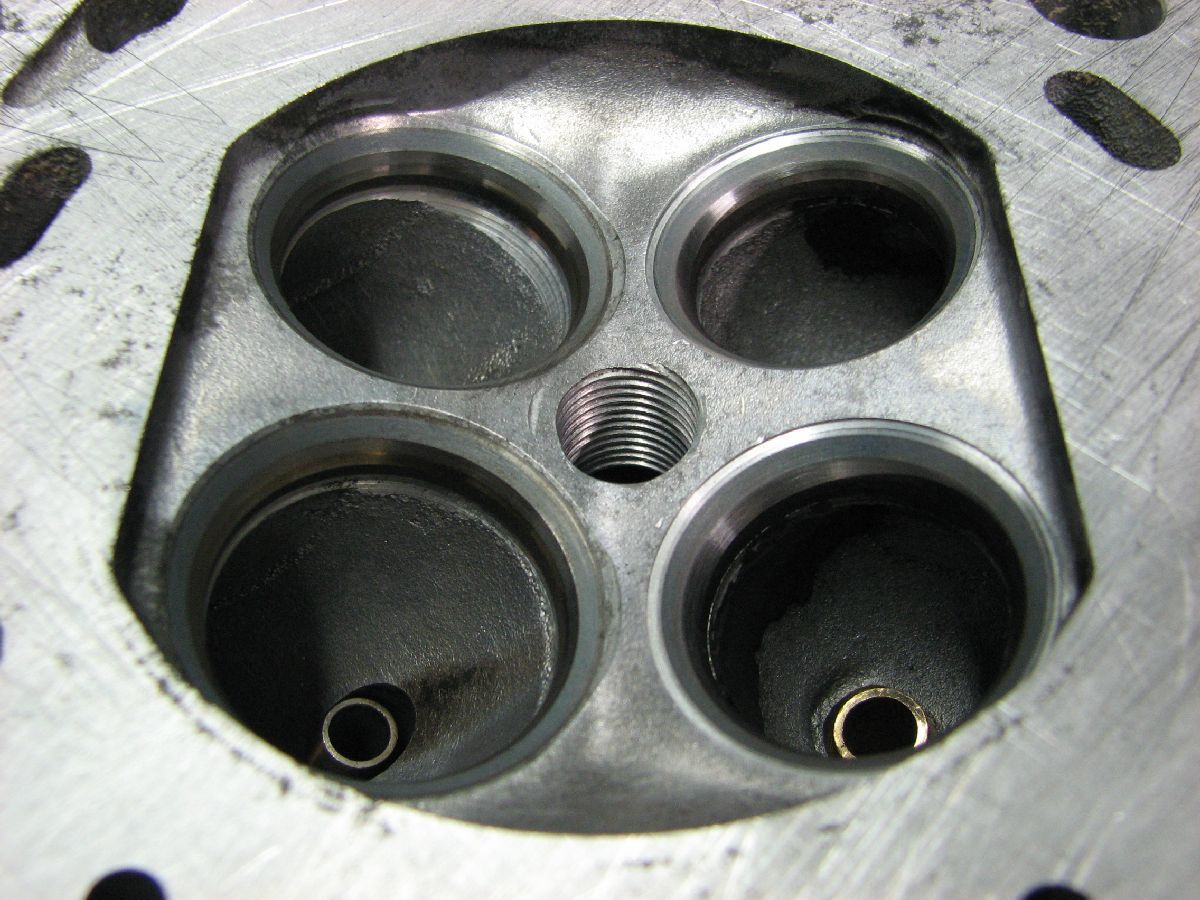

All valve seats recut using Serdi 100 valve seat cutting system

All valve hand lapped using grinding compound and checked for seal using machinists blue

Cylinder head gasket mating surface deck milled and hand stoned to prepare for metal head gasket

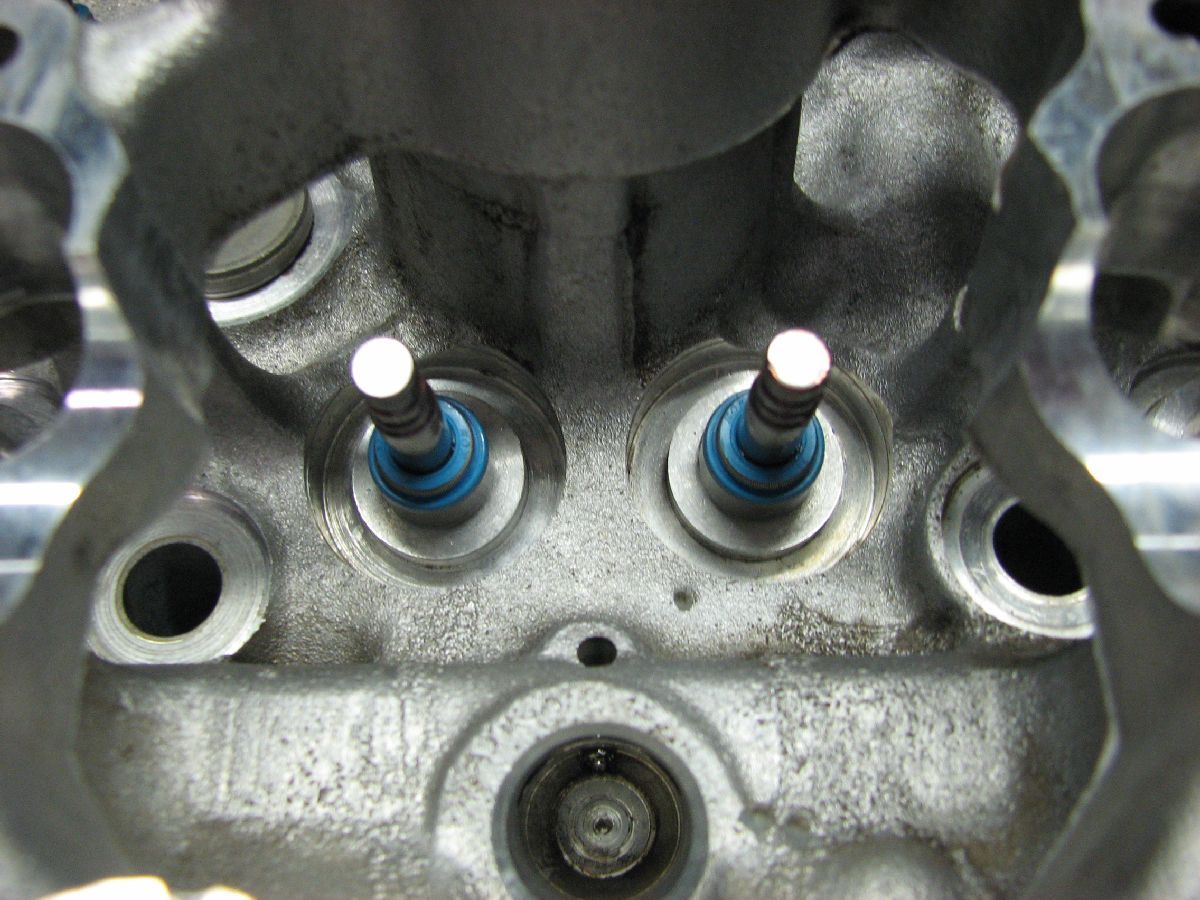

Viton valve stem seals

All valve springs, retainers, spring seats, and keepers checked for rust, pitting, and cleaned

All valves springs checked for pressure at install height and full lift using Rimac valve spring tester

Cylinder head carefully assembled and bagged for storage awaiting customer pick-up

Pictures of the cylinder head during the rebuild process: