This is a 2007 Porsche 911 Carrera S engine rebuild performed last summer. Luxury auto dealer contacted us with an inquiry and consultation inquiry. They had a beautiful 911 Carrera on the lot. The car ran great without any sign of problems. One day upon engine start-up there was white smoke from the driver tailpipe and a light engine misfire. Upon vehicle inspection it was agreed the engine shall be removed for further investigation. Internal engine damage was anticipated and eventually found. Upon cylinder head removal on Bank 2 the damage was found. Cylinder 5 liner cracked from headgasket mating surface down to the base of the water jacket. The piston dome was washed out with coolant which also washed out oil lubrication on cylinder walls leading to piston skirt and cylinder bore scuffing.

The following work was performed to restore the engine of this beautiful machine to new condition:

Cylinder Block:

- new cylinder block from Porsche

- oil pump disassembled, cleaned, inspected, gears and their clearances measured, compared to specification, found to be in good working order, lubricated with engine bearing assembly lube, reassembled, and installed on engine

- new crankshaft main, rod, and thrust bearing from Porsche

- all new piston rings from Porsche

- replace one piston with new unit from Porsche

- all miscellaneous o-rings, gaskets, head gaskets, and seals

- all bearing clearances checked and recorded

- all piston to cylinder bore clearances checked and recorded

- all piston ring gaps checked and adjusted as necessary

- new cylinder head bolts installed

- new crankshaft carrier bolts installed

- new connecting rod bolts installed

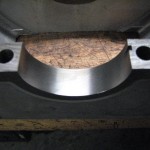

- piston dish volume measured and static compression ratio calculated

Crankshaft:

- crankshaft washed and micro polished

- all journal sizes measured and compared to factory specification

- crankshaft found to be in good condition and reused

Cylinder heads:

- camshaft cleaned, inspected, and journals micro polished

- cylinder heads disassembled, cleaned, and inspected

- cylinder heads deck milled equal amount and hand stoned with lapping stone to prepare for metal head gaskets

- valves reground using Kwik-Way valve refacing machine

- valve seats lapped in by hand and sealing checked

- cylinder heads reassembled with new valve stem seals

- combustion chamber volume measured and static compression ratio calculated

- after head installation on block, cylinder leak down checked

Pictures of the rebuild: