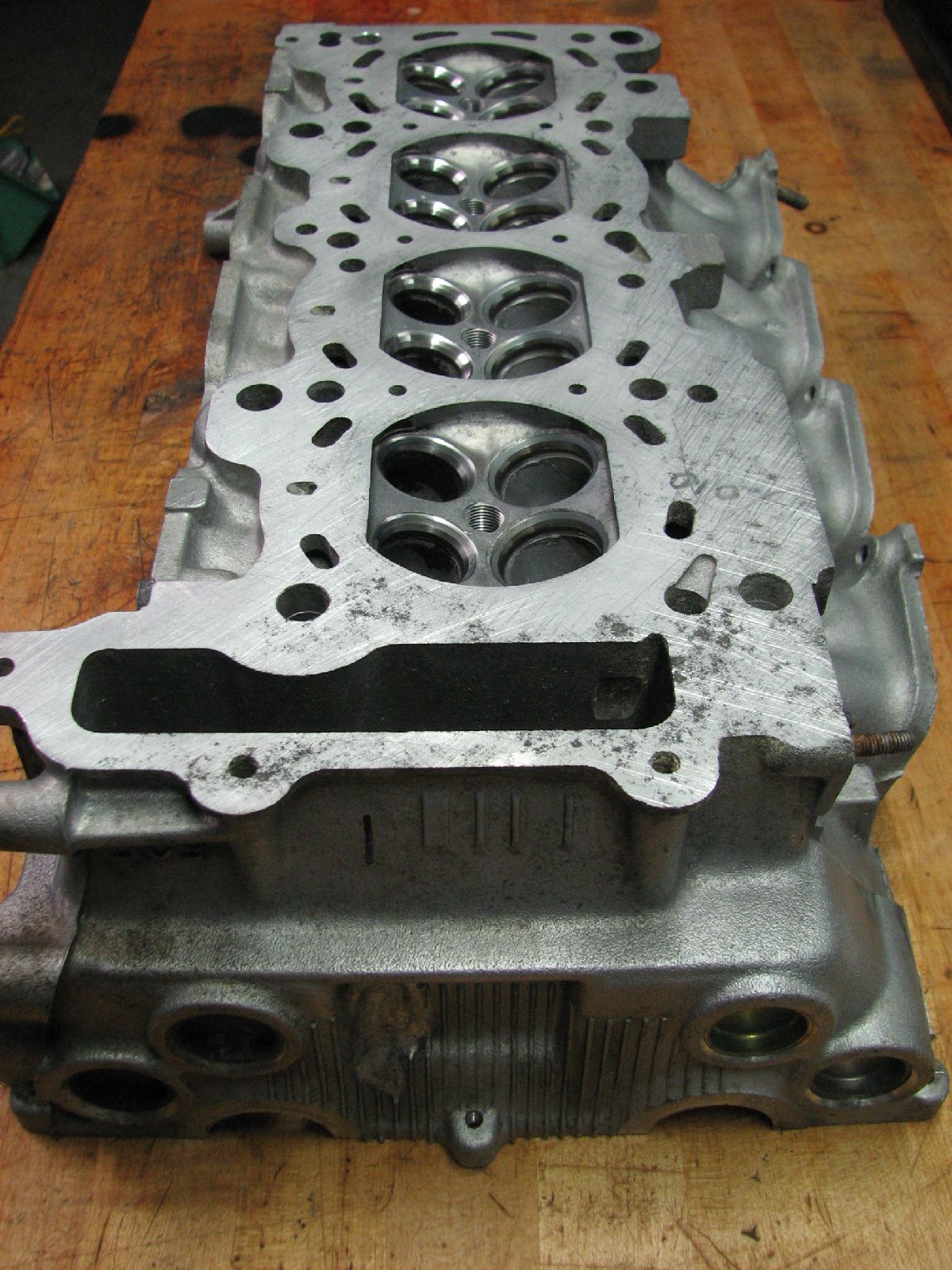

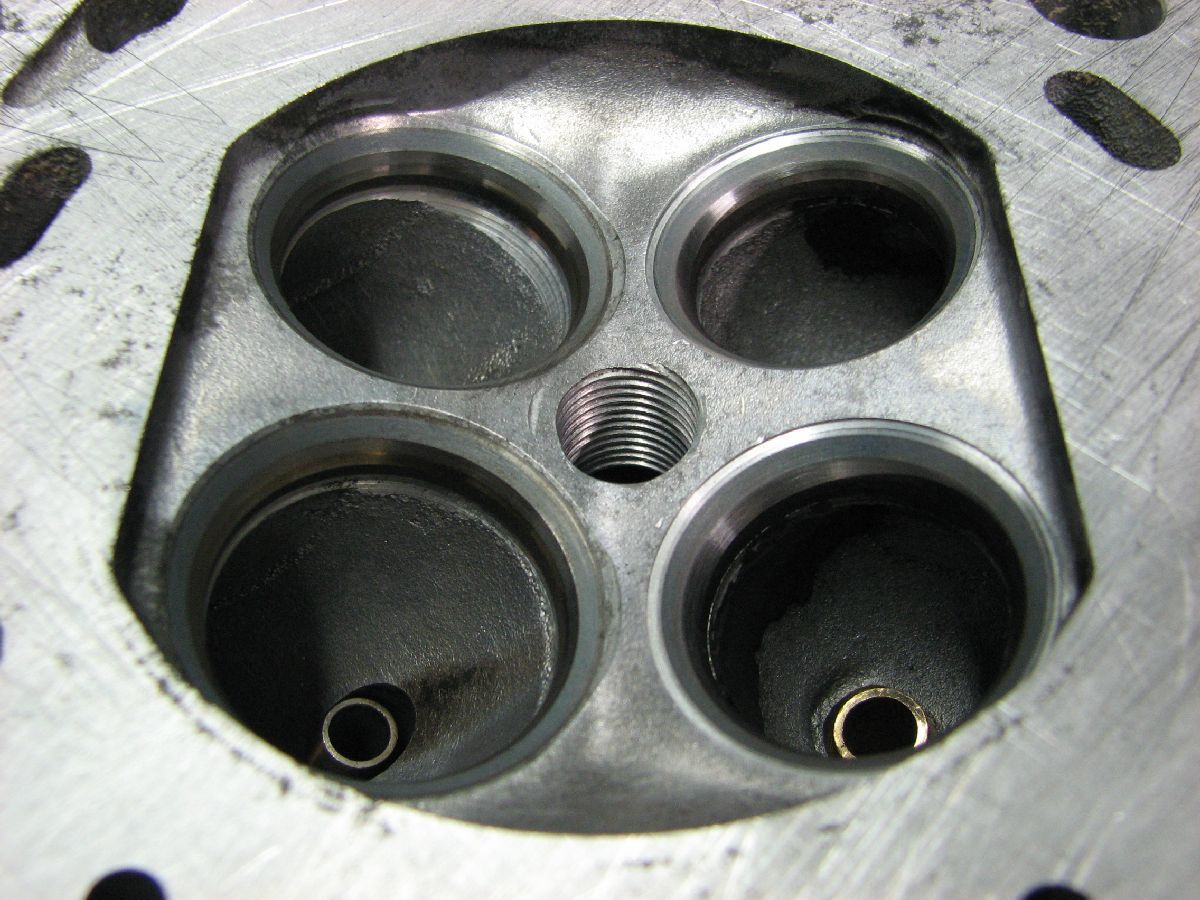

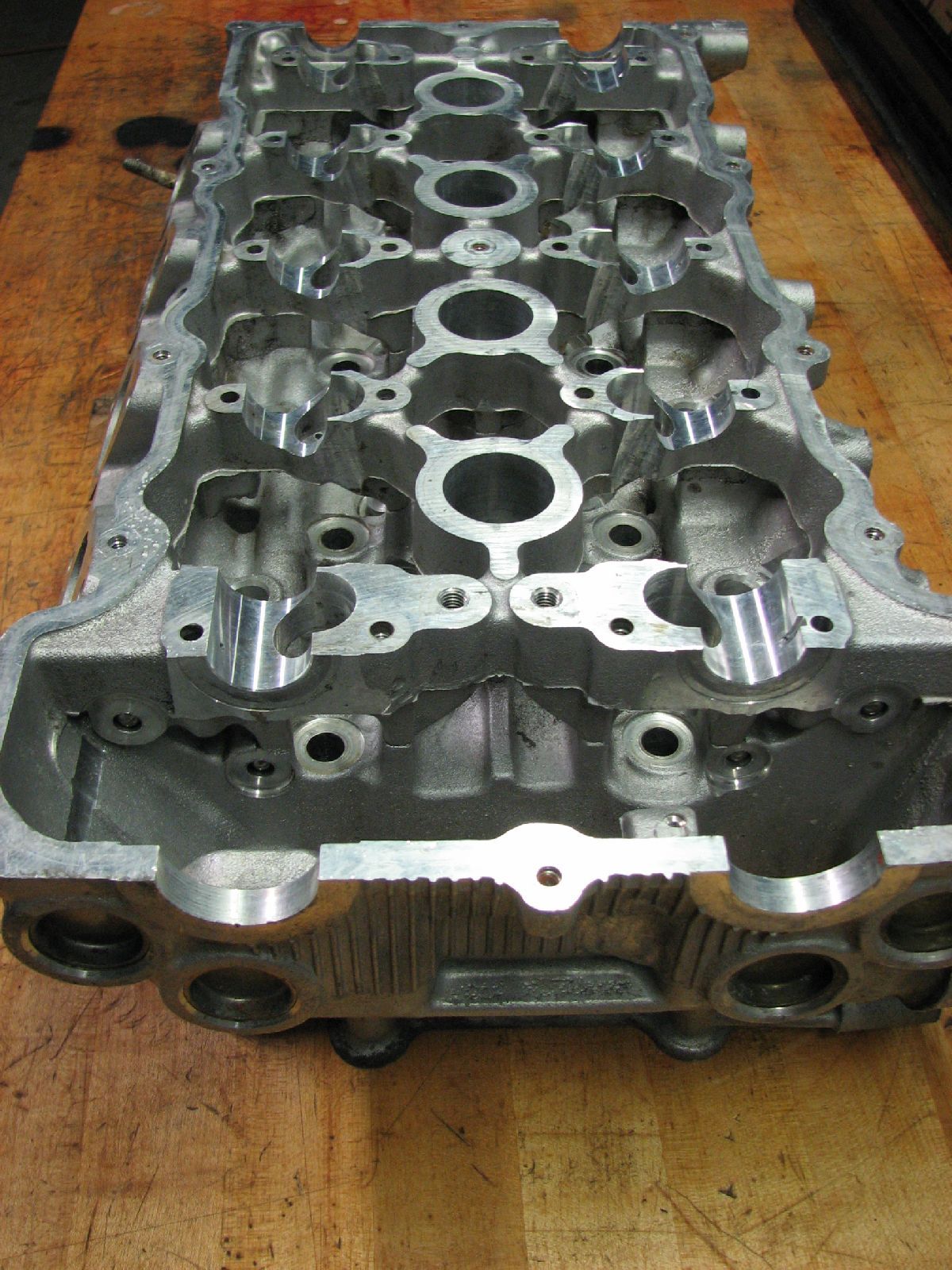

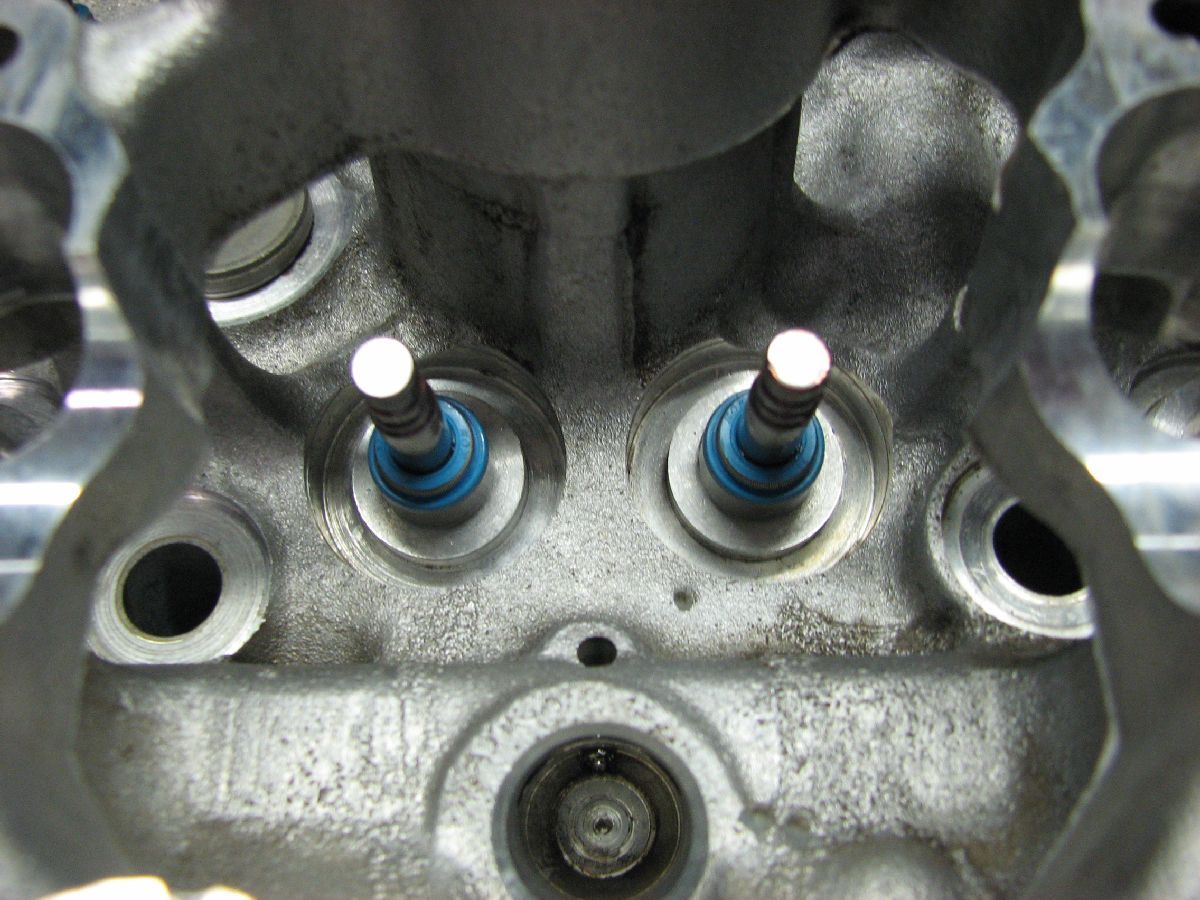

This is another turbine housing porting and blending job we did. This is a purposeful modification and not just another thing to add to your “modifications list”. Main purpose of turbine housing porting is to reshape the inlet and remove airflow restriction to the internal wastegate. Restrictive wastegate castings can lead to boost creep condition. We blend and reshape the turbine housing to increase flow to the wastegate valve and improve boost pressure control. Porting of the turbine housing, as typically performed by tuner shops, can actually be detrimental to performance and durability of the turbocharger. Turbocharger manufacturers spend millions of dollars on research and development of the optimal housing size and shape. Porting and removing of material will increase housing inner dimensions and leads to premature cracking. We blend casting marks of the turbine housing and polish it. Only material removal we do benefits wastegate exhaust gas flow characteristics.

This turbine housing porting and reshaping performed on a MHI(Mitsubishi Heavy Industries) TD05H-16G turbo, designed for a Subaru application. This turbo uses a 7cm turbine housing.

This turbo is a direct bolt-on for the following applications:

- 2002-2006 Subaru Impreza WRX

- 2004-2008 Subaru Impreza STI

- 2003 Saab 9-2x