Pavel’s Racing Engines is extremely excited to offer this product to the public. We have been testing these compressor wheels in various turbocharger models and engine combinations. Every time this product proves to make more power than its cast aluminum counterpart!

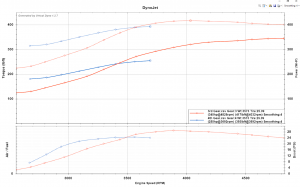

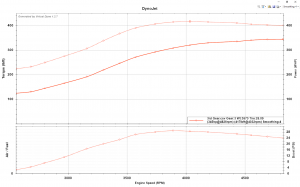

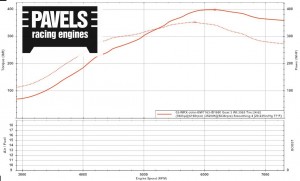

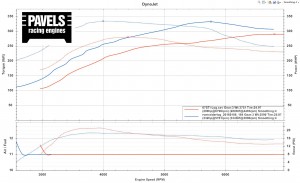

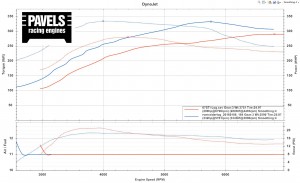

We tested these compressor wheels on the dyno with a consistent 25-30WHP gain at same boost level as stock cast wheel. Torque increase was moderate as well in the mid-range engine RPM. All testing performed on same vehicles within a narrow installation time window to reduce erroneous data.

This particular post focuses on billet compressor wheels for IHI VF-series turbocharger found on JDM, USDM, and UKDM Subaru Impreza WRX and STI vehicles.

COMPATIBLE TURBOCHARGERS:

- VF30 (JDM V5 STI)

- VF34 (ball bearing turbo)

- VF37 (twin scroll turbo, JDM V7/8 STI)

- VF39 (USDM 04-06 STI)

- VF43 (USDM 07 STI)

- VF48 (USDM 08-15 STI)

- VF52 (USDM 09-14 WRX, upgrade for 2008 WRX and 05-09 Legacy GT, originally VF40 or VF46)

PRE BILLET WHEEL FEATURES AND ADVANTAGE:

- 11 blade design: Conventional design is 6 tall and 6 short blades. Garrett has proven higher flow potential of the 11 blade design and it has been adopted to this compressor wheel for IHI application.

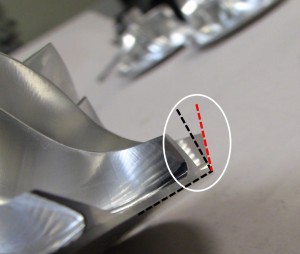

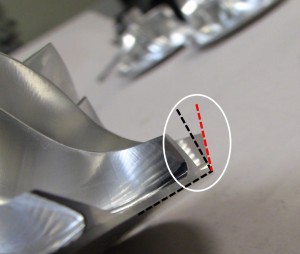

- Extended tip design: Conventional compressor wheel tips perpendicular to the exducer diameter. Extended tip technology originally developed as “cheater” compressor wheels for racing use. Standard exducer diameter is 60mm, while extended tip compressor wheels had 63mm exducer diameter for total blade area increase of 6%. This of it like a larger area of an airplane wing allowing for increased lift. The larger surface area allows for increased flow volume at same turbo speed.

- Slim blade design: Performance feature designed to increase air flow. Slim blades have a smaller cross-section allowing more area between blades for air. Flow is increased at same turbo speed. Thinner blades also weigh less for reduced moment of inertia and faster spool.

- Slim hub design: Another feature designed to increase air flow. Slim hub increased air volume with each rotation. Flow is increased at same turbo shaft speed. Smaller cross-section hub weighs less for a reduced moment of inertia and faster spool.

- Material selection: Conventional compressor wheels made by casting aluminum alloy. PRE compressor wheels machined from billet aluminum alloy block. Billet blocks are forged. This compacting of molecules increases material density and strength. Increased strength of billet material allows for reduced blade and hub cross-section and weight reduction without increasing internal stresses.

- Balancing: PRE compressor wheels inspected and computer balanced to less than 0.5g-cm^2. This does not mean compressor wheel should be swapped as-is. Stack-up dis-balance is always a factor and compressor wheel balancing should always be performed by a professional using entire rotating assembly.

Extended tip technology comparison: black dotted line is conventional design and the red dotted line is our billet wheel design.

Recently we dyno tested a couple of Subaru cars and recorded data logs. To keep this an apples-to-apples comparison we tried keeping the variable to a minimum. This comparison shows a 42WHP gain at 1.5psi LESS boost than stock turbo.

Car 1 (Red Line) 2007 Subaru Impreza STI

- Stage 1 rebuilt short block with 8.8 compression forged pistons

- stock rebuilt cylinder heads

- stock fuel injectors (maxed out at 21.5psi)

- stock fuel pump

- larger intercooler

- Perrin inlet pipe

- OEM rebuild VF48 turbo with cast compressor wheel (6/6 blade design)

- ECU tuned by 555 Motorsports

Cars 2 (Blue Line) 2010 Subaru Impreza WRX sedan, 5-speed manual transmission

- Stage 1 rebuilt short block with 8.6 compression Wiseco forged pistons

- stock rebuild cylinder heads

- stock fuel injectors (maxed out at 19psi due to higher flowing compressor wheel)

- stock fuel pump

- larger intercooler

- Perrin inlet pipe

- OEM VF52 turbo rebuilt with PRE billet compressor wheel (11 blade design) VF52 same size turbo as VF48. The only difference is compressor housing outlet orientation. All other internal parts same.

- ECU tuned by 555 Motorsports

Clink image to enlarge

You may purchase these billet compressor wheels from our eBay store:

PRE VF30 billet compressor wheel

PRE VF34 billet compressor wheel

PRE VF35 billet compressor wheel

PRE VF37 billet compressor wheel

PRE VF39 billet compressor wheel

PRE VF48 billet compressor wheel

PRE VF52 billet compressor wheel